Major Processes

SeAH Coated Metal manufactures a wide range of products with superior quality and exceptional characteristics based on the best surface treatment expertise in Korea.

CCL

(Color Coating Line)

- 1Steps 1 to 2

- 2Steps 3 to 4

- 3Steps 5 to 6

- 4Steps 7 to 8

- 5Steps 9 to 10

- 6Steps 11 to 12

- 7Steps 13 to 14

- 8Steps 15 to 16

- 9Steps 17 to 18

-

-

1. PAY OFF REEL

1. PAY OFF REEL

Uncoil the coated steel sheet coils and place the strips at the line entry

-

2. JOINER

2. JOINER

Connect the leading and trailing strips for a continuous process

-

-

-

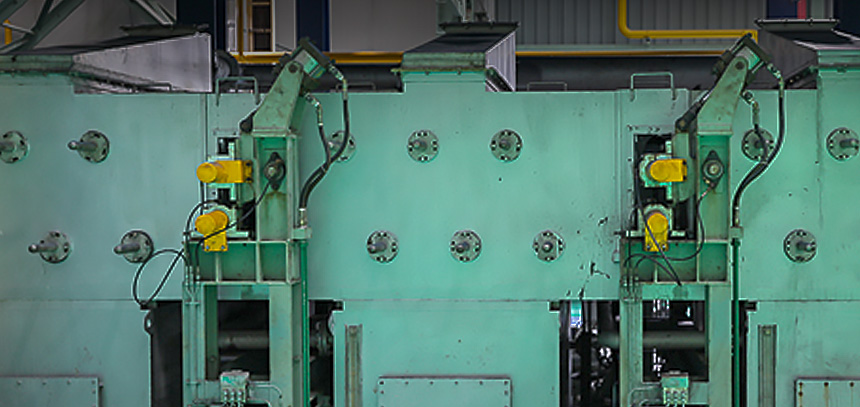

3. ENTRY ACCUMULATOR

3. ENTRY ACCUMULATOR

Equipment for accumulating strips for in-process storage of steel sheets when connecting coils at the entry section

-

4. CLEANING

4. CLEANING

Decontaminate the strips to improve the adhesion of the pretreatment agent

-

-

-

5. CHEMICAL COATER

5. CHEMICAL COATER

Equipment that applies a pretreatment to strips in order to enhance the adhesion between coated steel sheets and paint

-

6. CHEMICAL DRYER

6. CHEMICAL DRYER

Dry the pretreatment coated in the previous step

-

-

-

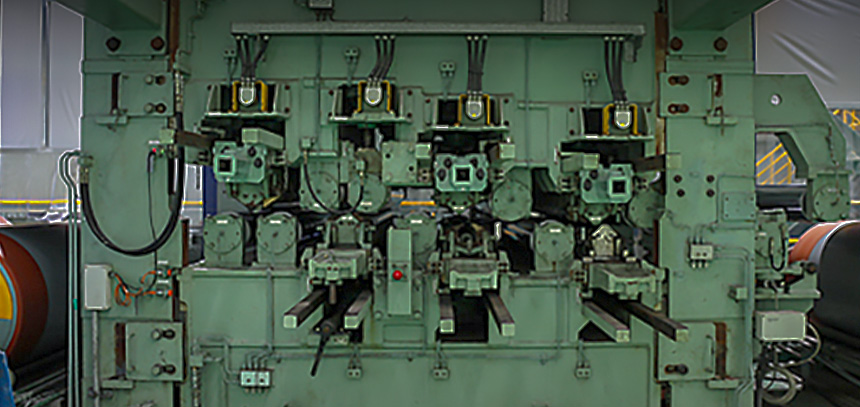

7. PRIME COATER

7. PRIME COATER

Equipment for applying an undercoat (primer paint) on the surface of pretreated steel sheets to enhance the adhesion of the topcoat (finish paint)

-

8. PRIME OVEN

8. PRIME OVEN

Dry the undercoat (primer paint)

-

-

-

9. NO1 FINISH COATER

9. NO1 FINISH COATER

Equipment for applying a topcoat (finish paint) to the surface of steel sheets treated with an undercoat (primer paint)

-

10. FINISH OVEN

10. FINISH OVEN

Dry the topcoat (finish paint)

-

-

-

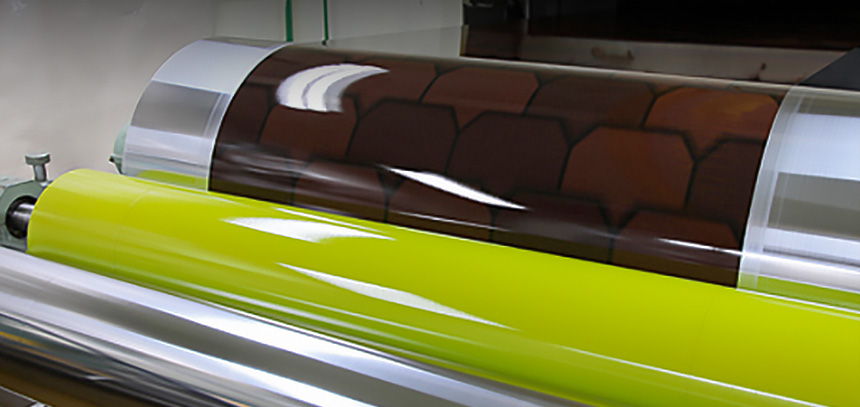

11. LAMINATOR

11. LAMINATOR

Equipment for adhering a film to a pre-painted steel sheet to impart graphics, patterns, image clarity, etc

-

12. 4도 PRINTER

12. 4도 PRINTER

Equipment for transferring patterns from pattern rolls of 1 to 4 colors to steel sheets with ink to produce various patterns

-

-

-

13. CLEAR COATER

13. CLEAR COATER

Equipment for applying a clear paint to the surface of a steel sheet that has been treated with a topcoat (finish paint) or a print

-

14. CLEAR OVEN

14. CLEAR OVEN

Dry the clear paint

-

-

-

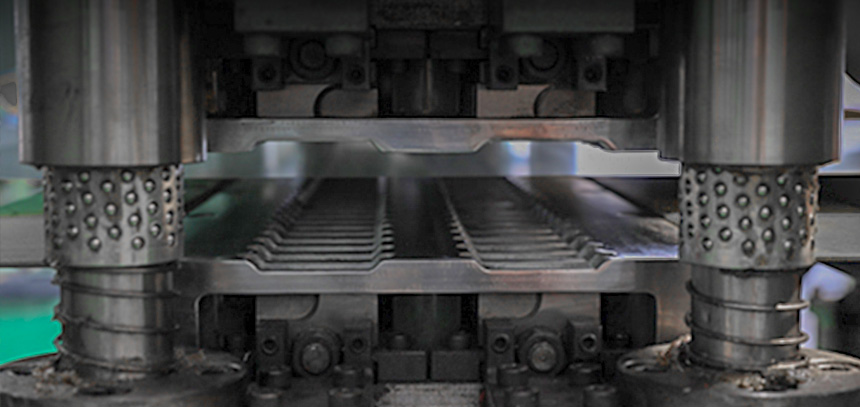

15. EMBOSSER

15. EMBOSSER

Equipment for transferring specific patterns (wood grain, leather, polka dots) by pressing a pattern roll onto the surface of a steel sheet

-

16. LEVELLER

16. LEVELLER

Apply elongation to the strips to give them flatness

-

-

-

17. EXIT ACCUMULATOR

17. EXIT ACCUMULATOR

Accumulate the strips in the exit section (tension reel) to store the steel sheets if shearing coils and delaying the process are required

-

18.

18.

Equipment for shearing painted strips and winding them into products

-