Major Processes

SeAH Coated Metal manufactures a wide range of products with superior quality and exceptional characteristics based on the best surface treatment expertise in Korea.

CGL

(Continuous Galvanizing Line)

-

-

1. PAY OFF REEL GROUP

1. PAY OFF REEL GROUP

After charging the full-hard steel sheets and welding the leading/trailing ends of the coil, transport them to the pre-cleaning section

-

2. PRE CLEANING

2. PRE CLEANING

Section in which a hot alkaline solution is sprayed onto the surface of strips to remove any foreign matter on the strips' surface

-

-

-

3. ENTRY ACCUMULATOR SECTION

3. ENTRY ACCUMULATOR SECTION

Equipment for accumulating strips for in-process storage of steel sheets when welding coils at the entry section

-

4. CLEANING SECTION

4. CLEANING SECTION

Apply further chemical degreasing to the surface of the pretreated strips using an alkaline solution and physical degreasing by brushing

-

-

-

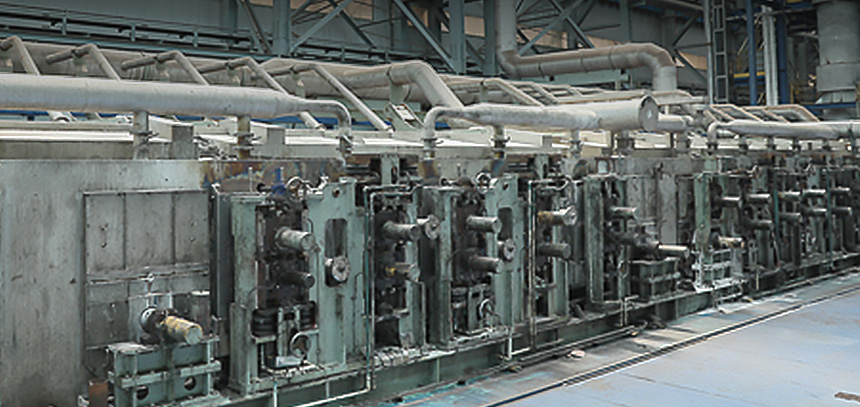

5. FURNACE SECTION

5. FURNACE SECTION

Heat/anneal the strips to the recrystallization temperature to restore their mechanical properties

-

6. ZINC POT & WIPING SYSTEM

6. ZINC POT & WIPING SYSTEM

Apply hot-dip galvanizing and air blowing to the surface of the strips to control the thickness of the coating

-

-

-

7. COOLING TOWER SECTION

7. COOLING TOWER SECTION

Cool the galvanized strips in the air before entering the skin pass section (skin pass mill)

-

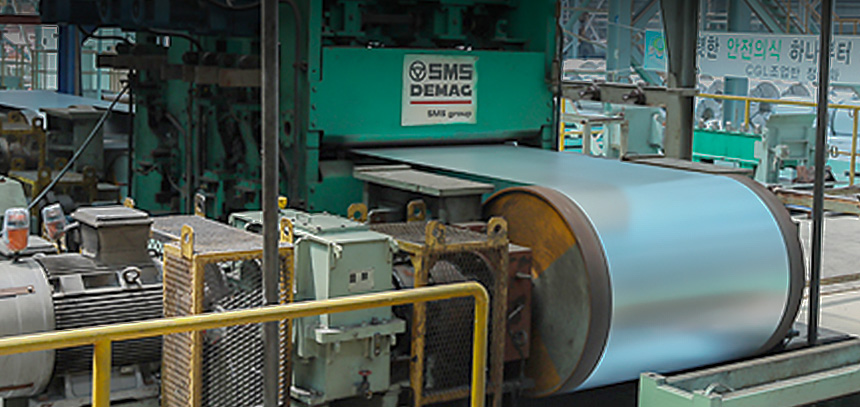

8. SKIN PASS MILL

8. SKIN PASS MILL

Apply skin-pass rolling to the strips to give them a surface roughness and improve their mechanical properties

-

-

-

9. TENSION LEVELLER SECTION

9. TENSION LEVELLER SECTION

Apply elongation to the surface of the skin-pass-rolled strips to give them flatness

-

10. POST TREATMENT

10. POST TREATMENT

Apply chrome to the surface of the strips to form a coating, and let dry

-

-

-

11. EXIT ACCUMULATOR

11. EXIT ACCUMULATOR

Accumulate the strips in the exit section to store the steel sheets if shearing coils and delaying the process are required

-

12. TENSION REEL GROUP

12. TENSION REEL GROUP

Shear the coated strips and wind them into a product, then proceed with oiling work as needed

-