Major Processes

SeAH Coated Metal manufactures a wide range of products with superior quality and exceptional characteristics based on the best surface treatment expertise in Korea.

CPL

(Continuous Pickling Line)

-

-

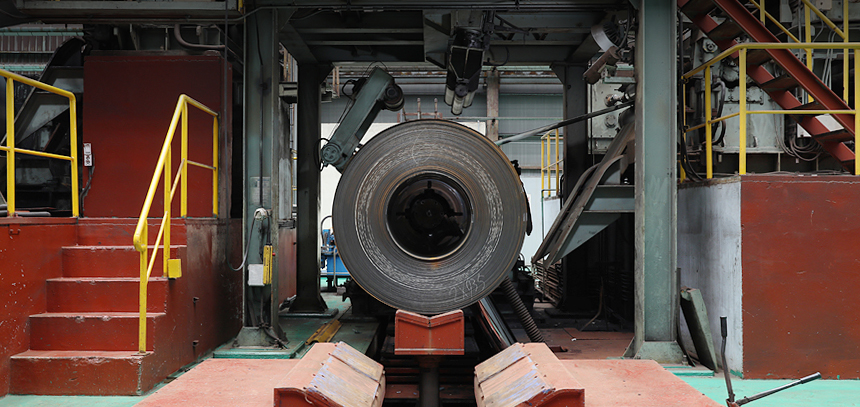

1. PAY OFF REEL

1. PAY OFF REEL

Charge the raw materials (hot coils), weld the coils' front and rear ends, and then transfer strips to the entry looper

-

2. ENTRY LOOPER

2. ENTRY LOOPER

Equipment for accumulating strips for in-process storage of steel sheets when welding coils at the entry section

-

-

-

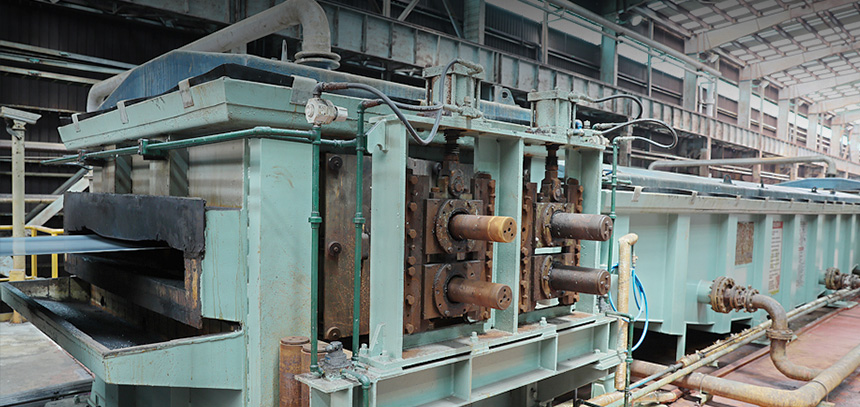

3. PICKLING SECTION

3. PICKLING SECTION

Equipment that removes scale from the surface of a strip by immersing or spraying it with a hydrochloric acid solution

-

4. RINSE SECTION

4. RINSE SECTION

Facility that removes residual hydrochloric acid solution from the strips in the pickling section with rinse water

-

-

-

5. EXIT LOOPER

5. EXIT LOOPER

Equipment for accumulating strips to store in-process steel sheets when drawing coils from the tension reel

-

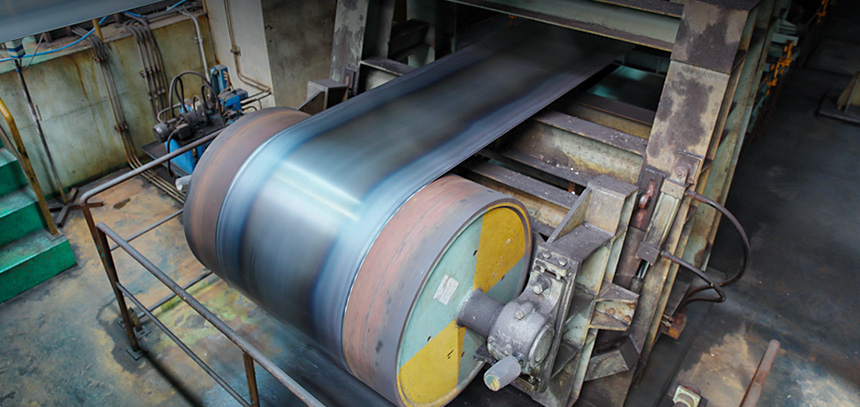

6. TENSION REEL GROUP

6. TENSION REEL GROUP

Perform the winding work for products and the oiling work for sales after cutting the pickled strips

-